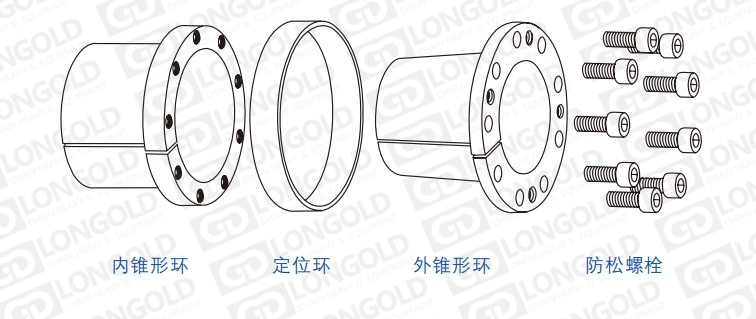

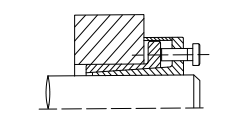

带法兰和外锥⾯的内孔与带内锥⾯的外环通过压紧螺钉组装在⼀起。

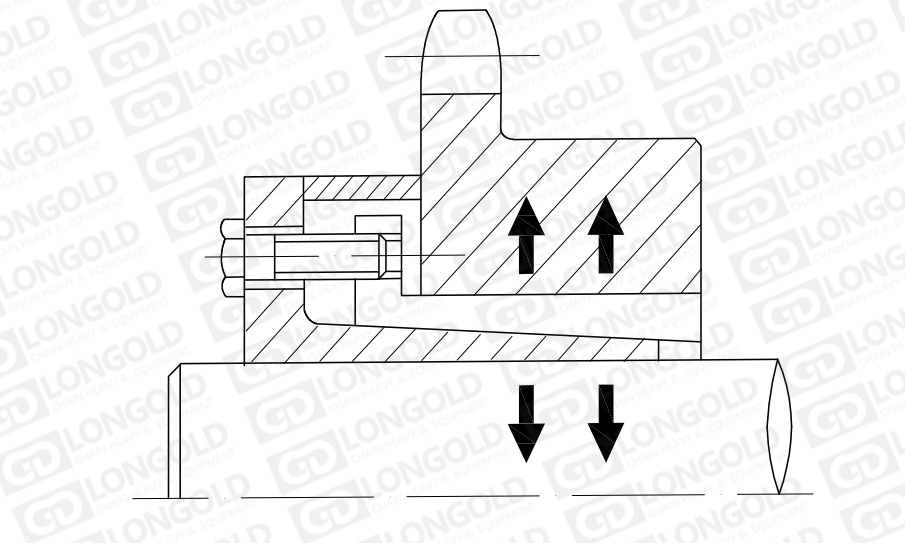

拧紧螺钉使内外环相对轴向移动,产⽣径向压⼒和摩擦⼒,使轮毂和轴联结在⼀起。

T型胀紧套内环与外环之间有⼀个定位环,起定位和密封作⽤。结构简单、能⾃动定⼼、安装同轴度好、密封性好、防尘防⽔。

Φ6-Φ130(mm)

额定传动扭矩:0.012-25kN·m

适⽤轴公差:h8

适⽤轮毂公差:H8

执行标准:JB/T 7934

对应国际型号:Z21

安全载荷、轮毂、设计保证系数、使⽤环境、轴的轴向载荷、传递转矩、所需轴直径。

点击图片放大

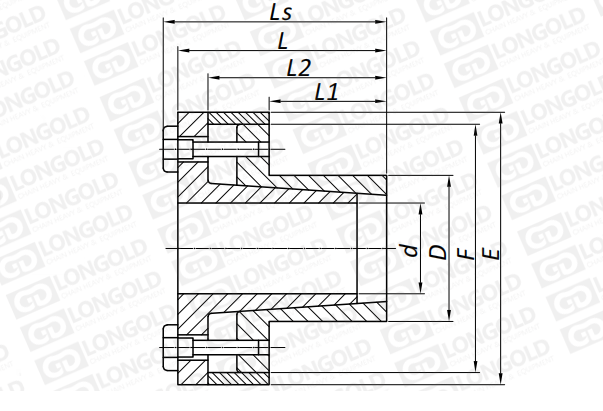

■产品本体结构详见如上图

上图为T型胀紧套的结构图。

可根据客户的需求,定制指定参数的产品,详细请咨询隆德技术人员。

■尺寸表

|

胀紧套型号 |

基本尺寸 |

内六角螺钉 |

额定负荷 |

对轴压力 |

对毂压力 |

螺钉拧紧力矩 |

参考重量 |

||||||

|

E |

F |

L1 |

L2 |

L |

Ls |

轴向力 |

转矩 |

||||||

|

Φd×ΦD |

Ft |

Mt |

Ps |

Ph |

Ma |

||||||||

|

mm |

mm |

mm |

mm |

mm |

mm |

mm |

规格×个数 |

kN |

kN·m |

Mpa |

Mpa |

N·m |

kg |

|

PL6x14T |

25 |

23 |

10 |

19 |

21 |

24 |

M3x3 |

4.2 |

0.012 |

185 |

80 |

2.0 |

0.15 |

|

PL7x15T |

27 |

24 |

12 |

22 |

25 |

29 |

M4x3 |

7.4 |

0.025 |

235 |

110 |

4.9 |

0.15 |

|

PL8x15T |

27 |

24 |

12 |

22 |

25 |

29 |

M4x3 |

7.4 |

0.029 |

205 |

110 |

4.9 |

0.16 |

|

PL9X16T |

28 |

25 |

14 |

23 |

26 |

30 |

M4x4 |

9.4 |

0.044 |

205 |

115 |

4.9 |

0.16 |

|

PL10x16T |

28 |

25 |

14 |

23 |

26 |

30 |

M4x4 |

9.8 |

0.049 |

185 |

115 |

4.9 |

0.17 |

|

PL11x18T |

32 |

28 |

14 |

23 |

26 |

30 |

M4x4 |

9.8 |

0.053 |

170 |

105 |

4.9 |

0.17 |

|

PL12x18T |

32 |

28 |

14 |

23 |

26 |

30 |

M4x4 |

9.8 |

0.058 |

160 |

105 |

4.9 |

0.18 |

|

PL13x23T |

38 |

33 |

14 |

23 |

26 |

30 |

M4x4 |

9.8 |

0.063 |

140 |

80 |

4.9 |

0.19 |

|

PL14x23T |

38 |

33 |

14 |

23 |

26 |

30 |

M4x4 |

9.8 |

0.068 |

130 |

80 |

4.9 |

0.20 |

|

PL15x24T |

45 |

40 |

16 |

29 |

36 |

42 |

M6x3 |

17.0 |

0.127 |

185 |

115 |

17.0 |

0.21 |

|

PL16x24T |

45 |

40 |

16 |

29 |

36 |

42 |

M6x3 |

17.0 |

0.136 |

175 |

115 |

17.0 |

0.23 |

|

PL17x26T |

47 |

42 |

18 |

31 |

38 |

44 |

M6x4 |

22.0 |

0.180 |

190 |

125 |

17.0 |

0.25 |

|

PL18x26T |

47 |

42 |

18 |

31 |

38 |

44 |

M6x4 |

22.0 |

0.200 |

180 |

125 |

17.0 |

0.27 |

|

PL19x27T |

49 |

43 |

18 |

31 |

38 |

44 |

M6x4 |

22.0 |

0.210 |

170 |

120 |

17.0 |

0.29 |

|

PL20x28T |

50 |

44 |

18 |

31 |

38 |

44 |

M6x4 |

22.0 |

0.220 |

160 |

115 |

17.0 |

0.30 |

|

PL22x32T |

54 |

48 |

25 |

38 |

45 |

51 |

M6x4 |

22.0 |

0.250 |

115 |

80 |

17.0 |

0.38 |

|

PL24x34T |

56 |

50 |

25 |

38 |

45 |

51 |

M6x4 |

22.0 |

0.270 |

105 |

75 |

17.0 |

0.41 |

|

PL25x34T |

56 |

50 |

25 |

38 |

45 |

51 |

M6x4 |

22.0 |

0.250 |

100 |

75 |

17.0 |

0.45 |

|

PL28x39T |

61 |

55 |

25 |

38 |

45 |

51 |

M6x6 |

33.0 |

0.465 |

135 |

97 |

17.0 |

0.47 |

|

PL30x41T |

62 |

57 |

25 |

38 |

45 |

51 |

M6x6 |

33.0 |

0.510 |

127 |

90 |

17.0 |

0.48 |

|

PL32x43T |

65 |

59 |

25 |

38 |

45 |

51 |

M6x6 |

33.0 |

0.540 |

120 |

90 |

17.0 |

0.52 |

|

PL35x47T |

69 |

62 |

32 |

45 |

52 |

58 |

M6x8 |

45.0 |

0.790 |

105 |

80 |

17.0 |

0.63 |

|

PL38x50T |

72 |

66 |

32 |

45 |

52 |

58 |

M6x8 |

45.0 |

0.860 |

100 |

75 |

17.0 |

0.67 |

|

PL40x53T |

75 |

69 |

32 |

45 |

52 |

58 |

M6x8 |

45.0 |

0.900 |

95 |

70 |

17.0 |

0.73 |

|

PL42x55T |

78 |

71 |

32 |

45 |

52 |

58 |

M6x8 |

45.0 |

0.950 |

90 |

70 |

17.0 |

0.78 |

|

PL45x59T |

86 |

80 |

45 |

62 |

70 |

78 |

M8x8 |

84.0 |

1.890 |

110 |

85 |

41.0 |

1.23 |

|

PL48X62T |

87 |

81 |

45 |

62 |

70 |

78 |

M8x8 |

84.0 |

2.010 |

105 |

80 |

41.0 |

1.24 |

|

PL50x65T |

92 |

84 |

45 |

62 |

70 |

78 |

M8x8 |

84.0 |

2.100 |

100 |

75 |

41.0 |

1.40 |

|

PL55x71T |

98 |

92 |

55 |

72 |

80 |

88 |

M8x9 |

94.0 |

2.600 |

85 |

65 |

41.0 |

1.70 |

|

PL60x77T |

104 |

98 |

55 |

72 |

80 |

88 |

M8x9 |

94.0 |

2.840 |

75 |

60 |

41.0 |

1.90 |

|

PL65x84T |

111 |

105 |

55 |

72 |

80 |

88 |

M8x9 |

94.0 |

3.070 |

70 |

55 |

41.0 |

2.21 |

|

PL70x90T |

119 |

113 |

65 |

86 |

96 |

106 |

M10x9 |

150.0 |

5.250 |

90 |

70 |

83.0 |

3.05 |

|

PL75x95T |

126 |

119 |

65 |

86 |

96 |

106 |

M10x9 |

150.0 |

5.600 |

80 |

65 |

83.0 |

3.32 |

|

PL80x100T |

131 |

125 |

65 |

86 |

96 |

106 |

M10x12 |

200.0 |

8.020 |

100 |

80 |

83.0 |

3.50 |

|

PL85x106T |

137 |

131 |

62 |

86 |

96 |

106 |

M10x12 |

200.0 |

8.500 |

95 |

75 |

83.0 |

3.81 |

|

PL90x112T |

144 |

137 |

65 |

86 |

96 |

106 |

M10x12 |

200.0 |

9.000 |

90 |

75 |

83.0 |

4.20 |

|

PL95x120T |

149 |

142 |

65 |

86 |

96 |

106 |

M10x14 |

230.0 |

11.000 |

100 |

80 |

83.0 |

4.75 |

|

PL100x125T |

154 |

147 |

65 |

86 |

96 |

106 |

M10x18 |

300.0 |

15.000 |

120 |

95 |

83.0 |

5.46 |

|

PL110x140T |

180 |

172 |

90 |

114 |

128 |

140 |

M12x12 |

290.0 |

16.000 |

80 |

65 |

145.0 |

6.05 |

|

PL120x155T |

198 |

187 |

90 |

114 |

128 |

140 |

M12x12 |

290.0 |

17.500 |

70 |

55 |

145.0 |

7.18 |

|

PL130x165T |

208 |

197 |

90 |

114 |

128 |

140 |

M12x16 |

384.0 |

25.000 |

90 |

70 |

145.0 |

8.03 |

|

PL |

130 | × | 165 | T |

|

(1) |

(2) |

|

(3) |

(4) |

(1)动力锁(胀紧套)

(2)轴径(mm)

(3)外径(mm)

(4)T型胀紧套

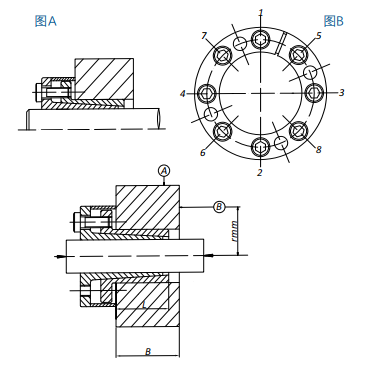

安装胀紧联结套

按图A,图B所示顺序,依次拧紧螺钉,分⼏次逐次拧紧螺钉直⾄达到螺钉拧紧⼒矩.

正确安装后,应按图3检验轴向跳动A≤0.05mm,径向跳动B≤0.002Rmm。

您在努力掌握如何开始自动化吗?

如果您正确实现以下目标,与我们的专家进行深入的对话可以让您少走很多弯路:

•提高生产力

•改进工艺和产品质量

•提高竞争力

•提高灵活性,满足客户多样化需求

与我们的专家进行一次一对一的交流,我们会帮助您利用协作机器人实现自动化。

|

|

|

|

|

|

隐私协议

|

|

|

|

本网站由广州隆德链条重机有限公司(以下简称“隆德链条”)创设。任何人士使用本网站前,请仔细阅读下列条款: |

|

|

|

本网站的资料、信息及其他内容由隆德链条提供,任何人进入本网站阅读任何内容、从本网站下载任何材料或使用本网站提供的资料,即表示同意遵守这些条款。这些条款构成隆德链条与您之间的协议。若不同意遵守这些条款,切勿使用本网站。隆德链条保留未经通知随时更新下列条款的权利,这些更新将同样也约束您。 |

|

|

|

|

|

|

|

权利声明

|

|

信息提交成功,谢谢!